What is a digital twin in utilities?

A digital twin in utilities is, as the name implies, a digital counterpart of a real-world object or process. It represents an up-to-date and accurate copy of a physical object’s properties and states. With the help of machine learning and simulations, a digital twin is able to optimize asset performance and utilization. For example – creating a digital twin in utilities allows asset owners to monitor and predict future breakdowns. Thus digital twins allow utilities companies to focus on preemptively maintaining their networks and assets where it is needed the most. This in turn allows keeping network interruptions to a minimum and saving on both maintenance and spare part costs.

Digital twin in the power grid

As we move further away from fossil fuels and towards renewable electricity-powered consumption, the importance of a stable and reliable transmission and distribution network rises exponentially. With more and more electric devices and automobiles being added to use every day, the strain put on power grids increases with it. For example, over the past 20 year time period, electricity consumption in the European Union service sector has risen +33,9% and in the household sector 16,5%. Those rates are predicted to increase even faster in the coming decades, with the electric car sector raising the total consumption amount to up to 25% in some areas. And seeing as most of the power grid we depend on, at least in Europe, was built right after the end of World War II, the importance of a well-maintained network cannot be overstated.

That is why companies are actively implementing new solutions to keep up with the demand and challenges of electricity consumption. By default, utility companies gather vast amounts of data on a daily and hourly basis. Every kilowatt-hour is logged and counted for. The amount of electricity it takes to read this article is measured precisely and taken into account when billing you for it. In addition to measuring the consumption amounts, the power grid operators have hundreds of other metrics they diligently take into account when operating their business. But all of that data has usually been used and analyzed retroactively, oftentimes when it is already too late to avoid a blackout or a fault. Meanwhile, digital twins in the utilities industry help to show both the current bottlenecks and future trouble spots in real-time, enabling the network operators to solve problems before they occur.

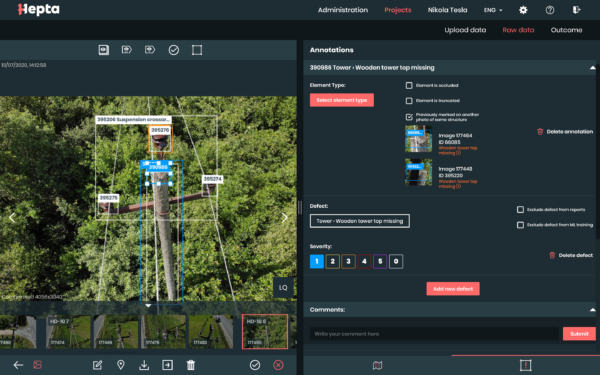

Hepta’s uBird platform used for power pole defect detection

With the help of a digital twin power grid, the network operators can collect and analyze data in real-time, making well-informed decisions faster and with a higher degree of certainty than ever before. Here, the vast amounts of data power grid operators collect give the companies significant advantages, helping them create predictive models based on their experiences and statistics. For example – when detecting an asset that has been starting to show elevated temperatures and knowing from previous experiences that these kinds of early signs lead to a fault 90% of the time, the network operator can choose to replace the asset at the earliest opportunity. In the past, the asset would have remained in use until it would either display obvious signs of damage or had already broken down and caused a blackout. It also allows grid operators to order needed supplies, spare parts or new machinery ahead of time and deliver them to areas they are required. With the help of digital twins in utilities, future trouble spots and hazards are planned for and solved today.

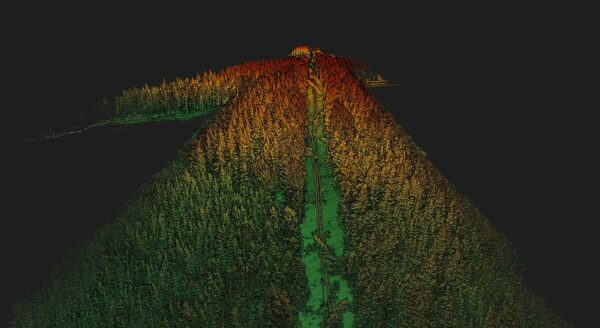

Another way digital twins are used in the utilities industry is the predictive maintenance of power lines. Currently, most companies look at the state of the grid from the current situation viewpoint. But with the help of power grid digital twin, simulations and analysis, the network operators can predict how the environment will affect the lines in case of storms or over a more extended period of time. While a line corridor might be clear of obstacles today, it might be overgrown before the next inspection cycle. Or the trees surrounding the powerline might be stable and far away currently, but when taking into account the weather simulations and previous data, we can see that the possibility of a storm falling a tree on the line is too high. Thus again, digital twins in utilities help to make better informed and future-oriented decisions.

Digital twin of a power line in Hepta’s uBird platform

The future of the digital twin in utilities

The combined length of all distribution lines in the world added up to 57,813Ckm in 2017. While it is estimated to reach 67,996Ckm in 2025, only a fraction of those lines are covered by digital twins. But as stated before, as the amount of stress being put on distribution networks grows, so does the need for proper maintenance, hazard detection and avoidance. Digital twins currently represent one of the best solutions for utilities companies to keep the grid well maintained and blackout-free. That is why electric grid operators are investing actively into digital twins and their implementation. In the near future, we will see the role of digital twins in the utilities industry rise rapidly due to their abilities, available data and amount of used algorithms giving network operators even better insights and quality feedback.

Should you have any questions regarding digital twins in the power grid inspections and how to implement them for your company, feel free to contact Hepta’s team of industry experts!