What kind of drone data analysis is used in power line inspections?

Drone data analysis helps power grid operators to detect defects that would be otherwise hidden from the naked eye. While traditional, on-foot inspection teams depend on what they see from the ground, drones enable inspection teams to both get a closer look at the power poles and use different sensors for data collection. In addition to that, drone data collection is over 200% faster than on-foot inspections and can give valuable insights regardless of the terrain. While on-foot patrols oftentimes struggle with inspecting power lines in marshes, wetlands, bogs and thick forests, drones fly over them freely and collect the drone data needed for analysis. The data collected with drones during inspections is then uploaded to Hepta’s power line inspection platform uBird, where drone data analysis can be easily conducted. Here, uBird allows users to use different inputs for inspections, such as:

- RGB drone data analysis

- LiDAR drone data analysis

- Infrared drone data analysis

RGB data analysis

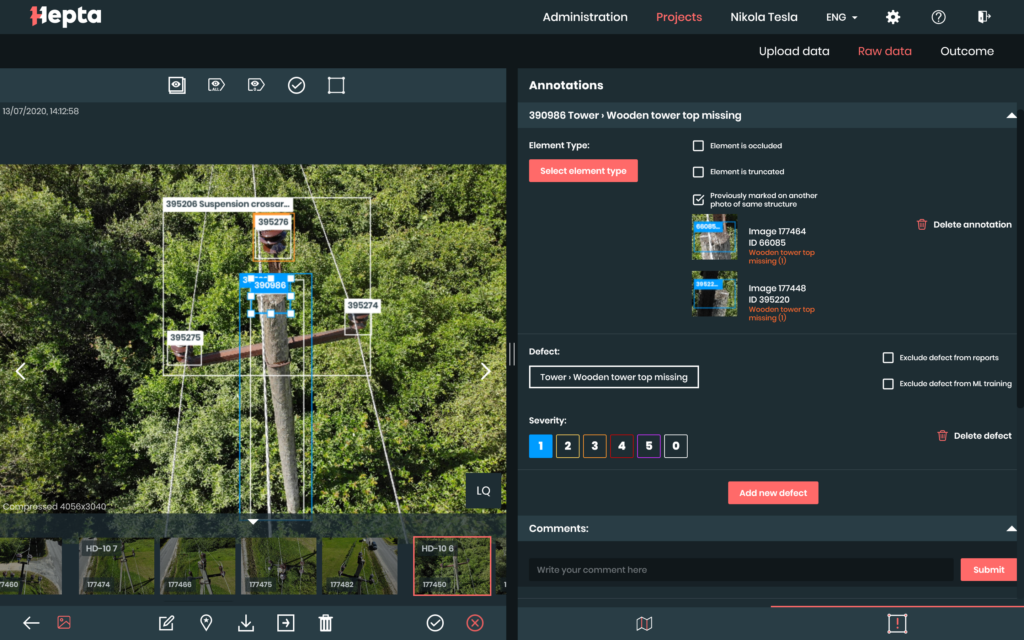

RGB data analysis relies on photos taken by drones during the data collection phase. Both distribution system operators (DSOs) and transmission system operators (TSOs) use RGB photos to detect defects that would otherwise be hard to see from the ground. As drones enable the inspection teams to get a top-down view of the power poles and lines, they get a total overview of the state of the asset. In addition to that, using drones for data collection allows the inspection teams to get close to the top of the poles or towers and take high-resolution images.

RGB photos are analyzed either manually by power line inspection experts or by machine learning algorithms in uBird. With manual analysis, the experts will go through the photos uploaded to uBird and mark found defects on photos. Broken wires, rust on details and assets, chipped and bent insulators – these are just some of the defects that are often detected from RGB photos. Manual RGB drone data analysis is always carried out in accordance of the guidelines and wishes of the power grid operator.

If the grid operator wants to employ machine learning algorithms to reduce inspection times and speed up the analysis process, Hepta will create brand new algorithms for the operator. This means that the machine learning algorithms will be based on the operator’s data, their assets and will look for the defects that the operator is most interested in. Regardless of the analysis process used, in the end, the operator will get a detailed overview of the state of their grid, see where the power poles and towers with defects are situated in an easily used, GPS-based map and be able to generate detailed work assignments for their ground crews from uBird.

LiDAR drone data analysis

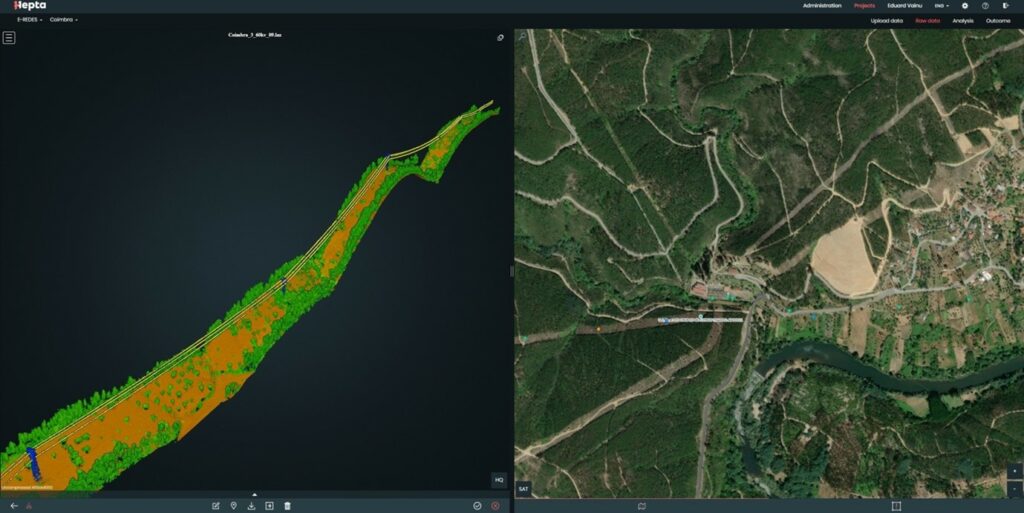

LiDAR is an abbreviation for Light Detection and Ranging, a remote measuring method that uses pulsed laser beams to measure distances between the LiDAR apparatus and the ground. The laser beams move constantly at the speed of light and reflect from the objects below the LiDAR, thus allowing to calculate the distance, based on the time it takes for the reflection to return. During the mapping process, every reflected laser beam creates a point with a calculated height. Combining all of the points (which there can be up to 400 per square meter) allows to create point maps and thus 3D models of the mapped area. LiDAR data is extremely accurate and allows for precise measurements to be used for mapping the inspected area.

Analyzing the LiDAR point maps enables grid operators to detect overgrown vegetation close to the power lines or poles. It also allows them to predict which trees might start to tilt dangerously in the future or could fall on the power lines during stronger storms. This allows grid operators to take preemptive actions, clearing the vegetation or cutting down trees before they start disrupting or severing the power supply.

In addition to vegetation analysis, LiDAR data is also used to detect sagging power lines. Power lines tend to sag either due to hot weather or because of increased power consumption. Sagging power lines create fire hazards when coming into contact with the surrounding vegetation. They also might pose a threat to the general public, such as to farmers who are in danger of coming into contact with the sagging power lines when driving their tractors on the fields. But through power line inspection data analysis using LiDAR point clouds, sagging lines can be easily detected, measured and reported.

Infrared data analysis

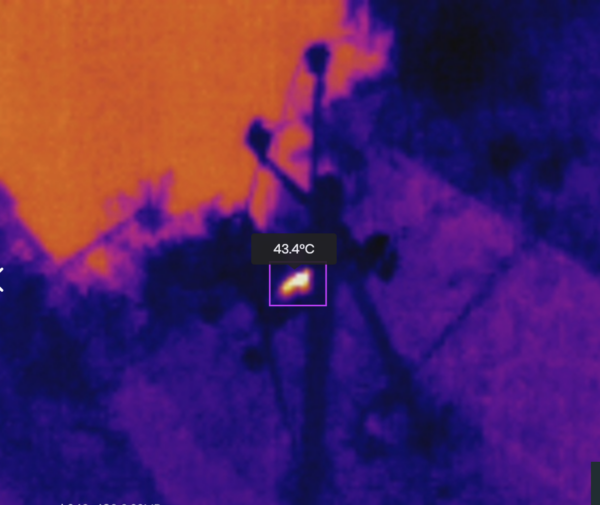

Using infrared images in power line inspection data analysis is most often done to detect overheating elements and the corona effect. The infrared data is collected using thermal cameras on drones.

Overheating elements are a clear indication of a possible near future breakdown of the asset and thus have to be fixed urgently. Detecting the overheating elements allows the grid operators to take preemptive measures to avoid blackouts and grid downtime. When analyzing the infrared data, it is quite easy to detect overheating elements on the pictures, as they are much hotter than surrounding parts and thus glow brightly in the thermal images.