Machine learning model creation and deployment in power line inspections

Machine learning models are created to recognize patterns and find specific details in huge datasets. For example, a machine learning model can help you find every photo containing wristwatches, from all of the photos you have taken in your life. But before you can employ a machine learning model, you will first need to create a machine learning algorithm.

The algorithm is a procedure that is run on data to create a machine learning model. The algorithm learns from the dataset it is based on and creates the basis for machine learning model creation. The ML model takes into account everything learned during the algorithm phase, such as rules or numbers. This allows the ML model to make predictions on the data it sees. Having learned the difference between wristbands and wristwatches, it can accurately predict what pictures are most likely to feature a wristwatch.

So how do the machine learning models work in power line inspections? Instead of wristwatches, we train our machine learning models to detect specific defects from images. Based and trained on the customer’s dataset, the ML models in Hepta’s power line inspection platform uBird look for defects the customer is most interested in. If the client has seen an increase of crooked insulators affecting the grid lately, we can create models that look for them in all of their inspection images. This enables the customer to inspect thousands of images in a couple of minutes, just by clicking on a button in uBird.

How does the machine learning model work in uBird?

Once a machine learning model has been created according to the customer’s wishes and specifications, it is added to uBird for the customer to use. The models are available for only the organisation they were created for, thus no sensitive information will be at risk. The machine learning model can be deployed at any time and on any of the customer’s lines.

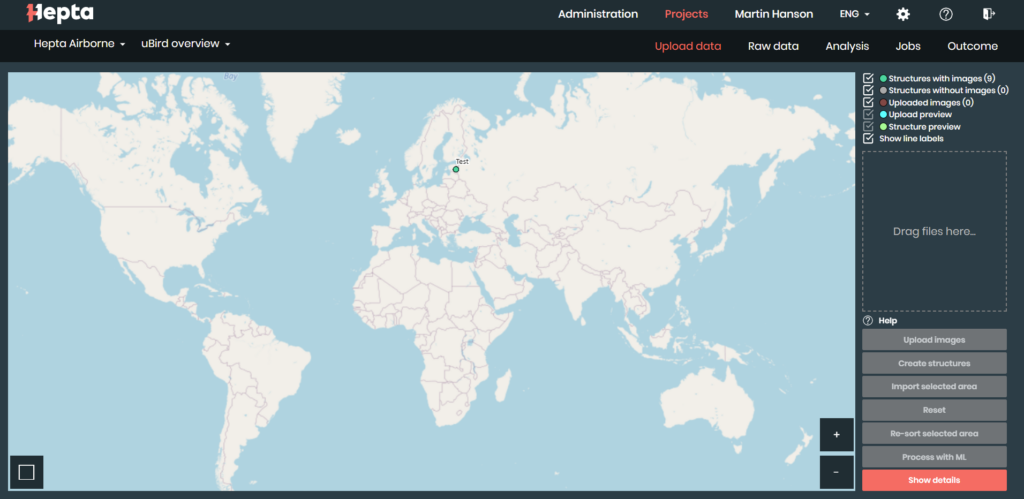

To run the machine learning model on your assets in uBird, first select the area you wish to inspect. You can select both new data and previously uploaded lines to be inspected by the machine learning model in uBird. Head over to the “Upload data” section, select the area on the GPS-based map and click on the “Process with ML” button.

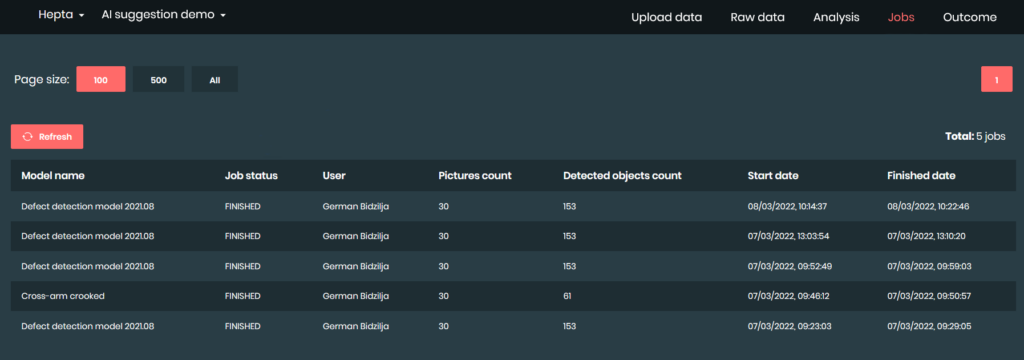

You can see the status of the machine learning model’s inspection process in the Jobs section. Once the model has finished its assignment, the AI suggestion results appear on the selected images.

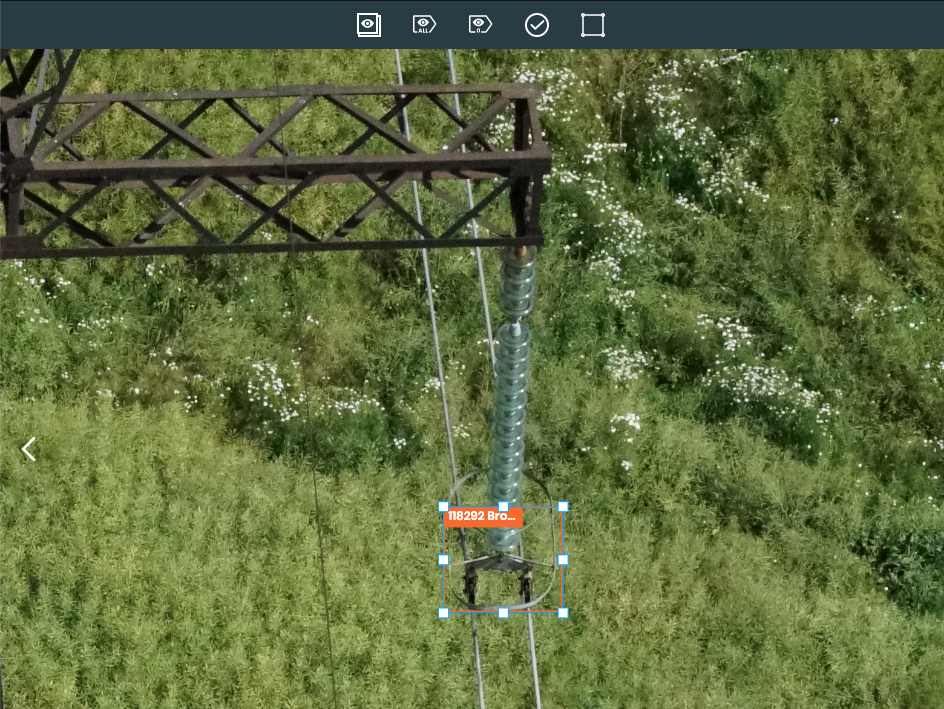

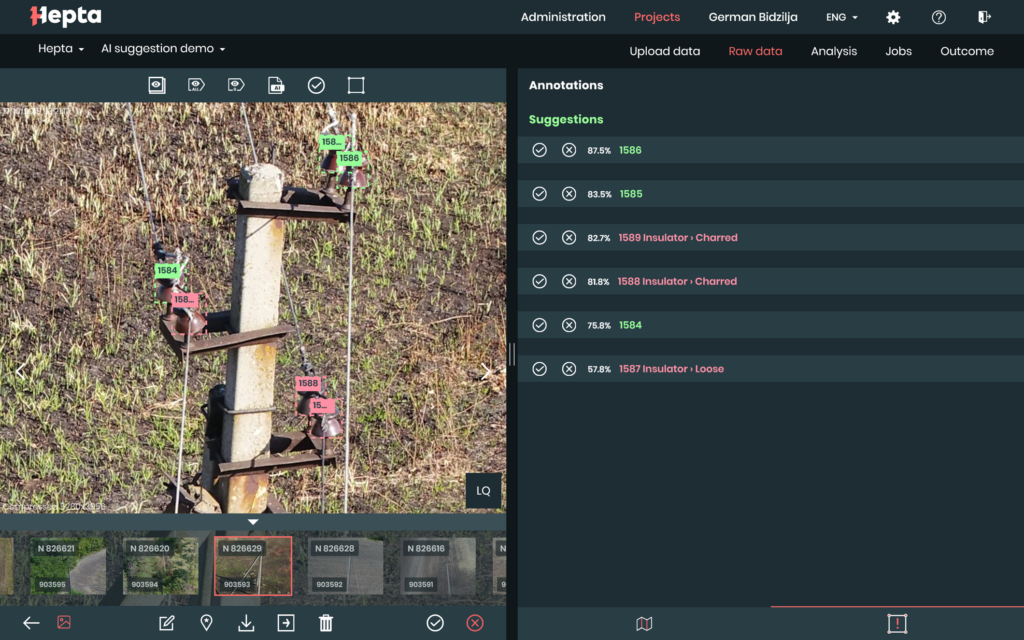

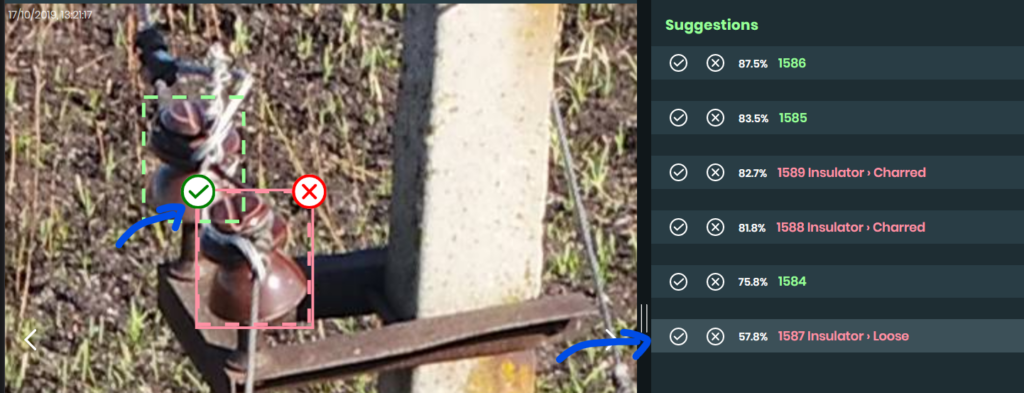

You can review the AI made suggestions of possible defects in the Raw data section. Here, the AI marks possible defects on images with pink bounding boxes and healthy elements with green bounding boxes. You can also see the confidence level of the AI annotations on the right hand side.

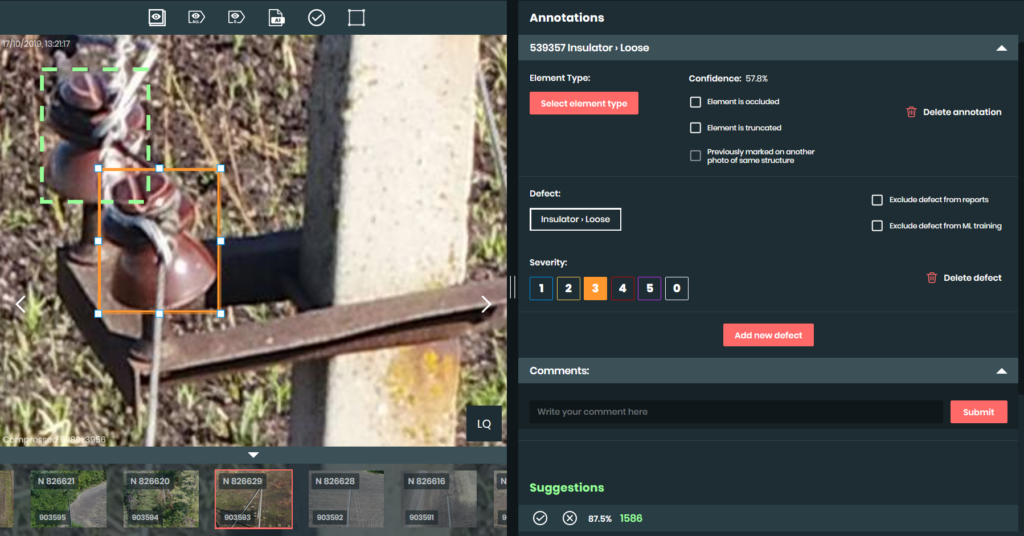

While reviewing the AI suggestions, you can accept them from the images or from the annotation list on the right. When looking at the images, the accept/reject buttons appear when you hover over the bounding box.

You can change the annotation freely after you have accepted the AI suggestion. For example, you can change the box size, severity level, defect type, element type, etc.

You can also hide the AI suggestions at any time, using the filter above. The AI suggestions are not included in the reports and can be safely ignored if you don’t want to review all of them.

Viewing the results

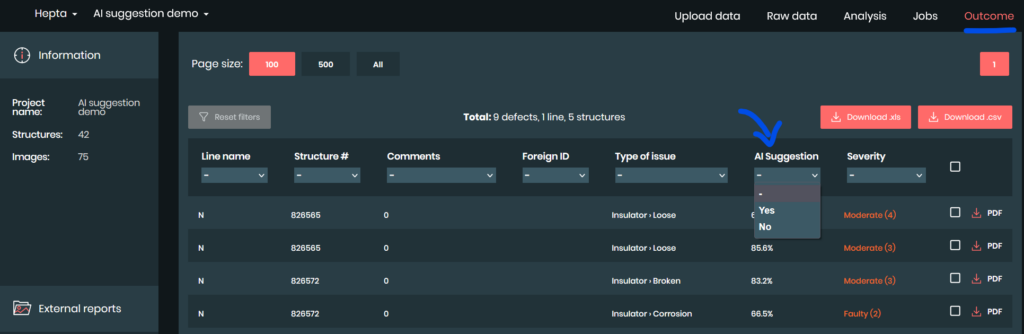

You can see and filter the inspection results on the Outcome page in uBird. You can view only the defects that were originally suggested by the AI by selecting “AI suggestion” filter “Yes”, or exclude any AI results by selecting “No”. The default value is “-” and will include both manual and AI suggestion results.

As an end-result, running the machine learning models in uBird allows companies to:

- inspect thousands of images for defects in just a matter of minutes

- find more relevant defects

- and to speed up their inspection process